KEVINS RED WINE

This is how I make the red wine that our family enjoys.

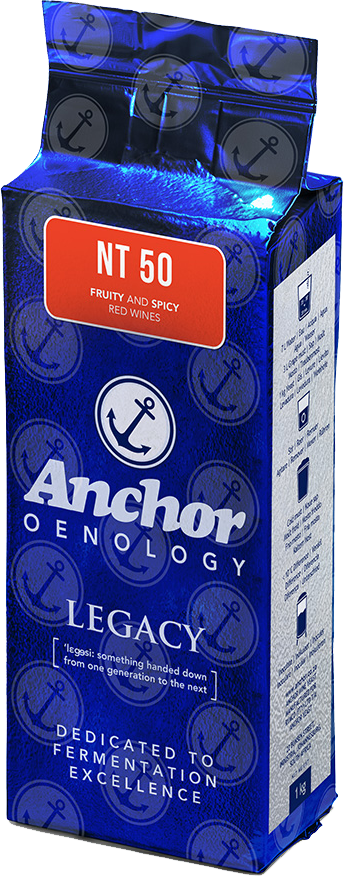

No surprise that I use a cultured yeast and will bounce around between BM45, D254, Maurvin B, CSM, and Alchemy 4 depending on what I have available and the season. I also use Go ferm, Fermaid and optired with DAP on hand in case I smell some H2S. I add 2g/l of untoasted oak chips to bind with any green tannins and adjust TA to about 6.5 (depending on pH). I then ferment for 10 days. I should say that I was fortunate to learn red wine making from a very good family friend as well as Inniskillin founder Dr. Karl Kaiser. Karl insisted on a 10 day ferment (not 9 and not 11). After ferment I press and then let rest for a couple of weeks to settle, followed by a racking and addition of 4-5 g/L toasted oak chips, MLB and optimalo (added separately). The wine is stored at 20C for at least 1 monh until MLF is finished. I then rack off chips and sediment and add at least 50ppm FRESH KMS (5g/50L). I then age the wine in barrels either neutral or new. If I am using new barrels then I will not add the toasted oak chips during MLF. Age as long as possible, making sure barrels are full and monitor the free sulphite levels.

I use mother nature in January to cold stabilize all our wines by placing them in -3C temps for about 10-14 days and then back to 5-10 C storage.

Prior to bottling I adjust the acidity in reds to KK target #s of 3.5 pH and 5.55 TA.

Remember that adding acid to finished wine is difficult so if needed I add prior to ferment. If I need to strip some TA then I prefer a few small adjustments to keep an eye on pH (which usually increases with the TA reductions).

KEVINS WHITE WINE

This is how I make our family’s white wines.

Like red wine I use a cultured yeast depending on the variety and add 1g/L DAP, goferm, fermaid (as per “yeast starter” tips).

Our juice is very clean so nutrient is a must to prevent H2S.

I ferment at cool tempertures and aim for a very long slow ferment. I also ferment until completely dry. After fermentation is complete I let rest for a couple of weeks and then rack and add at least 50 ppm FRESH KMS (unless I plan on MLF on a batch). I then wait for January to cold stabilize (noted in the red wine notes above) as well as bentonite addition of approx. .9g/L (depending on test). After cold stabilized I return wine to 5-10 C storage and rack off bentonite in 3-4 weeks. I then filter the wine to polish. Prior to April bottling. I may add 2-3 g/L of dextrose and or some arabica gum if I feel it softens the wine. If sugar is added then sorbate will be needed as well. Free KMS is checked and wine is ready for bottling.

These notes are here to help you in your winemaking and are by no means the only way to make wine. As an extreme, you can leave your pail in the fall sun and eventually it will be wine, but please don’t share with us. Wine making is a hobby and understanding and “feeling” the stages of change and development will very much add to the fun. We hope that this helps you.

The Watsons

Recommendations For a Yeast Starter

Recommendations For a Yeast Starter